Nozzles

Fiber-reinforced polymer (FRP) flanges or nozzles play a vital role in industrial applications, particularly in the construction of tanks and vessels. These components are strengthened with fibers like fiberglass to enhance their durability and resistance to corrosion. Their primary function is to establish a secure and leak-proof connection point for pipes or other equipment, ensuring a reliable linkage that withstands th challenges of corrosive environments. FRP flanges contribute to the longevity of systems that handle liquids, offering a robust solution to prevent leaks and maintain structural integrity.

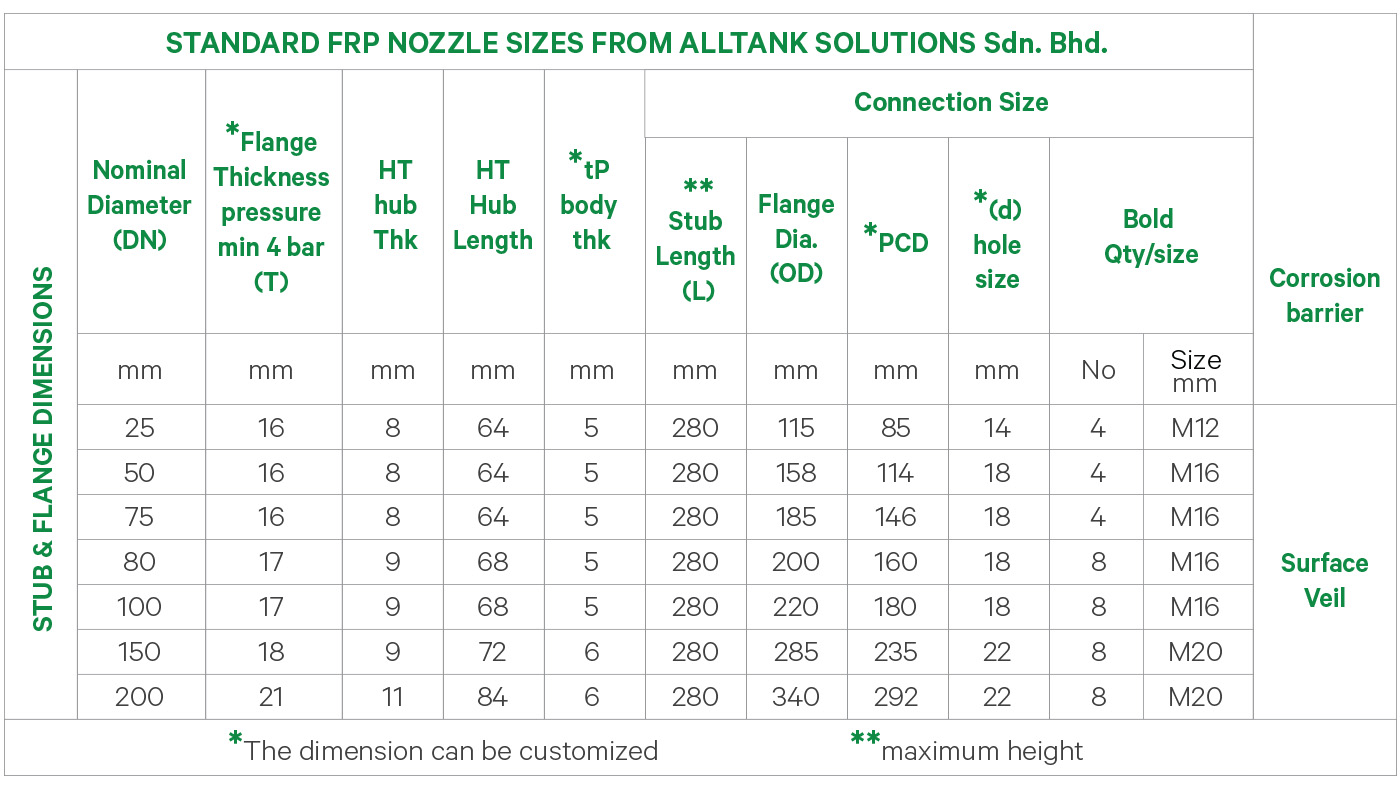

- Manufactured to conform to ANSI 150, AS2634, AS2129, BS EN 13121

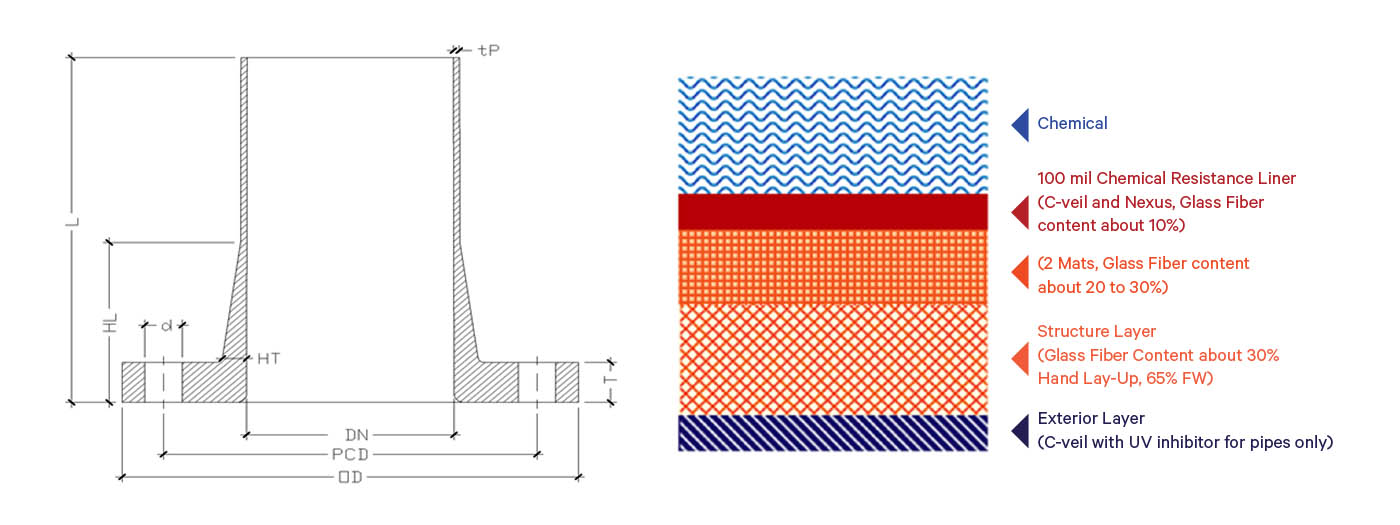

- C-veil and Viledon + 2 Mats 100mil resin rich corrosion liner

- Hand lay, integral type construction, woven roving used continuously from flange face to hub for 3 inches size and larger

- Uniform external surface and stub end surface prepared for immediate bonding

- Bolt holes of drilled flanges are spot-faced and coated with resin

- MEKP (C + N Liner) & BPO (C + 2N Liner) cure system

- Standard inventory available in Vinyl Ester Resin, Derakane Momentum 411-350, 441-400, Eterset 2920, MFE 711P, Swancor 901-3, Crystic 671 etc…

To supply equivalent resin system can be available upon request